Restriction and Prohibition of Hazardous Substances

In order to produce more environmentally-friendly products, we have a clearly defined division of works and responsibilities, develop hazardous substances free technical standards and have constructed an eGreen IT platform to collect hazardous substance data from suppliers. We also announce the requirements and standards on the Supplier Relationships Management (SRM) platform and hold internal and external trainings with our suppliers.

Chemical Substance Management

Improve chemicals management to reduce impact

To maintain health and protect the environment, we comply with the requirements of customers and regulatory authorities, and strictly require our suppliers to restrict or forbid their use of listed controlled substances. For example, all Pegatron products comply with the requirements of RoHS directives. In addition, TBBP-A (Tetrabromobisphenol-A, C12H12Br4O2, CAS-No. 79-94-7) is a Brominates Flame-Retardant (BFR) and harmful to human health and ecosystems. We require covers, casings, electronic components and other internal plastic parts of all our products must have concentrations of less than or equal to 0.1% (1000 ppm) of TBBP-A. We also commit to avoiding the use of cables, connectors, and PCBs which contain TBBP-A.

Hazardous substance restriction list

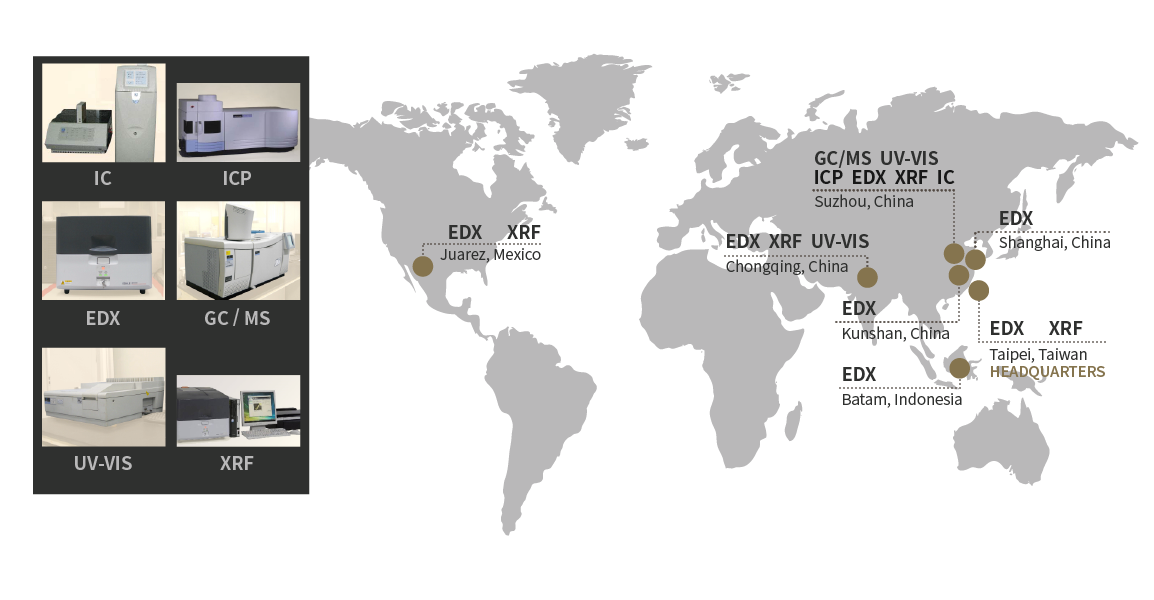

Laboratories and Testing Methods

Professional testing to ensure requirements are met

We have established chemical laboratories to carry out hazardous substances tests. We use a X-Ray Fluorescence Spectrometer (XRF) for quick screening of hazardous substances (Pb, Cd and Hg) and detection of total chromium and bromine to prescreen Cr6+, PBBs and PBDEs. We also set up labs to use inductively coupled plasma mass spectrometer (ICP) to analyze lead, cadmium, mercury and other metal elements, ultraviolet light absorption spectrometer (UV) and gas chromatography mass spectrometer (GC/MS) to test the content compliance test of organic compounds such as Cr6+ and brominated flame retardants and plasticizers respectively, and purchase ion chromatography (IC) equipment to detect the halogen content of high-risk parts such as PCB and external cables. We require suppliers to use appropriate hazardous substance testing methods, such as IEC 62321, to verify compliance of electrical and electronic parts, including ICs, chipsets and metal plating.

Hazardous Substance Control Program

Control hazardous substances to meet responsibilities

To ensure all our products meet the requirements of being hazardous substance free and requirements from customers and regulatory authorities, we have set up several stages to control hazardous substances.

• SPT-00001 PureGMS HSF Technical Standard

• SPT-00002 PureGMS Low-Halogen and Halogen-Free Technical Standard

• SPT-00004 Technical standard of Environmental Labels in computer products, televisions

2.Produce green products by implementing a hazardous substances reduction plan.

3.Meet customer requirements by using green product spec comparison tables to compare customers’ and our requirements.